hartattak1

Member

- Joined

- Aug 6, 2012

- Messages

- 7

- Reaction score

- 0

Hi

I have a Mark IV combo with SUS-4, so it has the 400mm spacing for the mount holes.

I recently bought a Mark headshell, unfortunately it has the non SUS-4 416mm spacing.

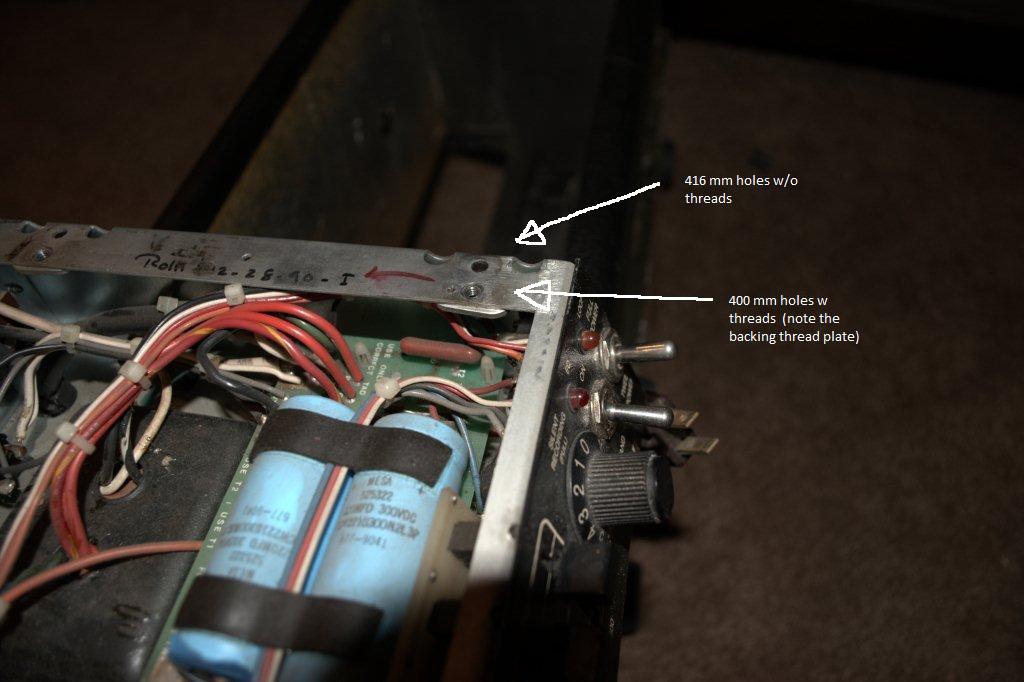

My Mark IV chassis has holes for 400mm and 416mm spacing, however only the 400mm spacing will accept threads. It looks like there is a little metal piece, 10mm x 5mm x 1mm with threads that the mounting screws attach to the 400mm holes, but not the 416mm holes.

Does anyone know how these metal pieces are attached to the chassis? I tried to tap it out gently with a hammer, but it doesnt look like it moved at all. I dont see any weld marks, so I'm completely in the dark as to how these things hold. If I could get these things removed, or another set, then I can just use the existing holes in the headshell and the chassis.

Thanks for any info.

I have a Mark IV combo with SUS-4, so it has the 400mm spacing for the mount holes.

I recently bought a Mark headshell, unfortunately it has the non SUS-4 416mm spacing.

My Mark IV chassis has holes for 400mm and 416mm spacing, however only the 400mm spacing will accept threads. It looks like there is a little metal piece, 10mm x 5mm x 1mm with threads that the mounting screws attach to the 400mm holes, but not the 416mm holes.

Does anyone know how these metal pieces are attached to the chassis? I tried to tap it out gently with a hammer, but it doesnt look like it moved at all. I dont see any weld marks, so I'm completely in the dark as to how these things hold. If I could get these things removed, or another set, then I can just use the existing holes in the headshell and the chassis.

Thanks for any info.