WireNut

Member

I've seen several folks post regarding converting their combos to heads. This is something I've wanted to do for a long time, as the combo is just too clumsy to move easily.

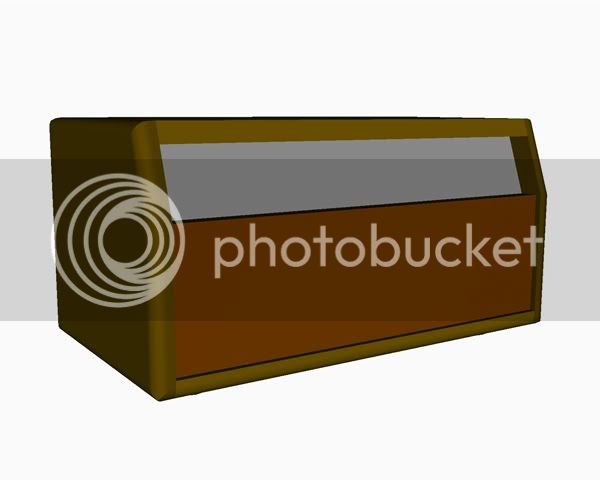

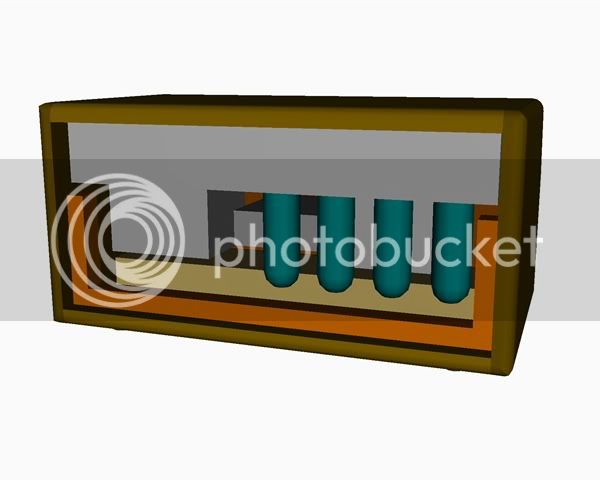

I finally took the plunge and made myself a prototype head. I'd like to re-do this someday with a nice hardwood and dovetail joints, but I don't have a dovetail jig at the moment. I used high quality, cabinet grade 11 ply void free Birch, which is nice because it's very strong but light, and lightening this beast up was a major goal. I used plate joinery (bisquits). Finish is 5 coats of marine grade spar urethane.

For cabinets, I wound up making 3 identical 1x12 cabs out of the same birch ply, but with different back options: one is a full closed back, one is ported, and one is a half-back I can run open or add the top have to configure it as a closed back. I re-used the EV 12 from the combo in one, and a Celestion Vintage 30 in the others.

I used the closed back cab playing out this weekend, and I was pretty happy with the results. In spite of it being ply, it sounded pretty warm and pleasing, no nasty harshness that I could hear.

Bottom line, it was well worth the effort - 100 bucks or so in materials and a few hours in the shop with the football games on. If you're inclined to give it a try, I say go for it, it wasn't real complicated.

Now I've got an empty combo shell, StudioSlips cover, and flight case to get rid of.

-WireNut

I finally took the plunge and made myself a prototype head. I'd like to re-do this someday with a nice hardwood and dovetail joints, but I don't have a dovetail jig at the moment. I used high quality, cabinet grade 11 ply void free Birch, which is nice because it's very strong but light, and lightening this beast up was a major goal. I used plate joinery (bisquits). Finish is 5 coats of marine grade spar urethane.

For cabinets, I wound up making 3 identical 1x12 cabs out of the same birch ply, but with different back options: one is a full closed back, one is ported, and one is a half-back I can run open or add the top have to configure it as a closed back. I re-used the EV 12 from the combo in one, and a Celestion Vintage 30 in the others.

I used the closed back cab playing out this weekend, and I was pretty happy with the results. In spite of it being ply, it sounded pretty warm and pleasing, no nasty harshness that I could hear.

Bottom line, it was well worth the effort - 100 bucks or so in materials and a few hours in the shop with the football games on. If you're inclined to give it a try, I say go for it, it wasn't real complicated.

Now I've got an empty combo shell, StudioSlips cover, and flight case to get rid of.

-WireNut