I have a '76 original Boogie Mk I which I want to mount in a newer Mesa hardwood cab, which used to house a Mk I reissue.

However, the mounting holes on the newer reissues are closer together (wider chassis flanges) than on the old ones. I don't want to drill the beautiful hardwood cab for new holes, so I have to come up with a different solution.

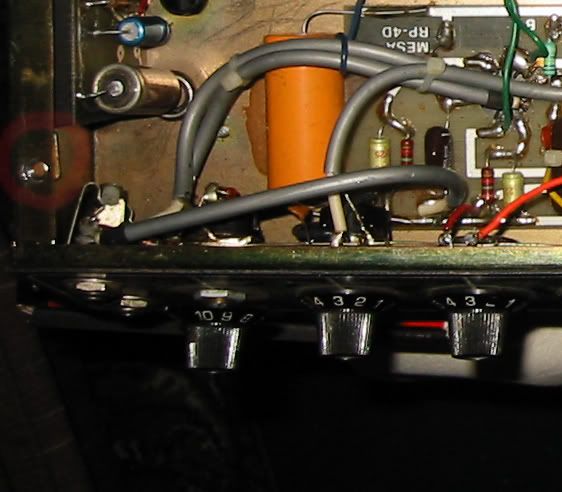

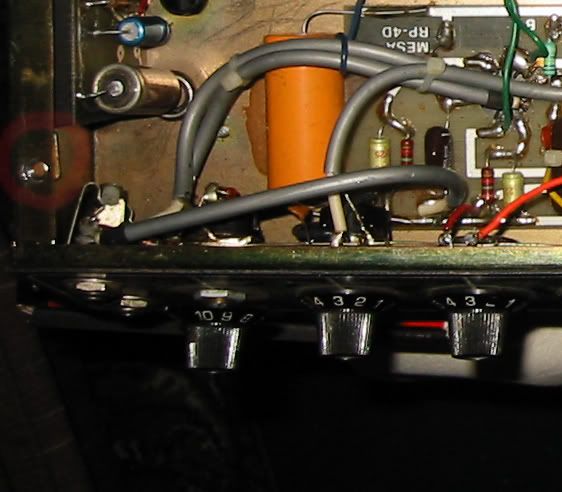

To do that I need, among other things, mounting nuts for the original mounting screws used on the reissue amp. As you can see in the photo below of the '76 amp, there are some pre-drilled nuts that have been inserted below the chassis flange with the actual nut sticking through a hole in the chassis flange. What I need is four of those "bits" that you can see in the photo. Am I making sense here? The problem is, I have no idea what they are called, so I don't even know where to begin to search... Can anyone help?

However, the mounting holes on the newer reissues are closer together (wider chassis flanges) than on the old ones. I don't want to drill the beautiful hardwood cab for new holes, so I have to come up with a different solution.

To do that I need, among other things, mounting nuts for the original mounting screws used on the reissue amp. As you can see in the photo below of the '76 amp, there are some pre-drilled nuts that have been inserted below the chassis flange with the actual nut sticking through a hole in the chassis flange. What I need is four of those "bits" that you can see in the photo. Am I making sense here? The problem is, I have no idea what they are called, so I don't even know where to begin to search... Can anyone help?